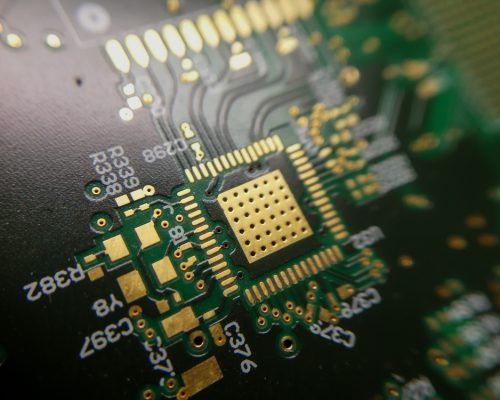

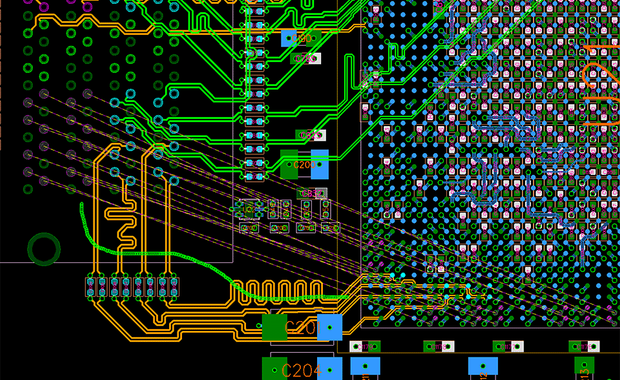

Standard printed circuits

The cost of the PCB is an important component in the price of your electronic product. PCB-FAB supports you in your printed circuit manufacturing needs, while offering you impeccable quality.

For a prototype or series production, PCB-FAB offers you its standard printed circuit services

- Free tooling costs

- Systematic electrical test

- Economic process or urgent VIP process

- Technical and commercial service at your service

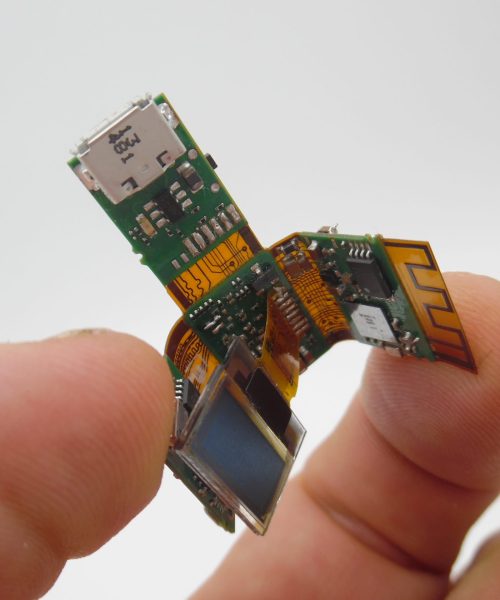

Why use Flex & Flex-Rigid technology?

Flex and flex-rigid PCBs have been widely used in a variety of applications and markets for many years where space and size are critical to the operation of a product as an interconnect between connectors or with d ‘other rigid printed circuits.

At PCB-FAB, we are helping more and more customers to migrate to Flex & Flex-Rigids due to the advantages of its construction, some examples as follows:

- 3D interconnection

- 1 piece component (compared to several rigid PCBs and wire harnesses)

- Increased reliability

- Space saving

- Reduced labor costs during assembly

- Fully tested as an integrated component

- Inventory one piece

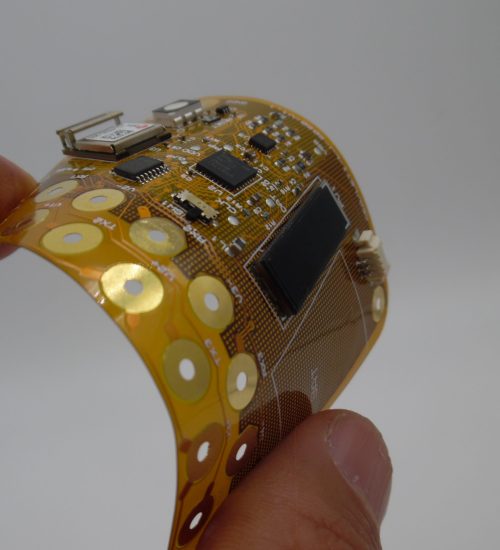

The Flex & Flex-Rigid team

PCB-FAB has set up a flexible manufacturing team responsible for management. The flexible team now allows all variants of Flex & Flex-Rigid to be manufactured both within industry deadlines and with high quality.

PCB-FAB manufactures Flex-Rigid circuits using simple layered or composite constructions, up to 76ųm Track & Gap and also offers the incorporation of HDI technology (100ųm ųmVia).

Our Flex team is currently involved in customer projects and uses their expertise to improve circuit integrity, reduce additional lead times and reduce costs.

PCB-FAB has dedicated CAM engineers for Flex & Flex-Rigid technologies to minimize tooling time and further increase support and feedback to design managers.

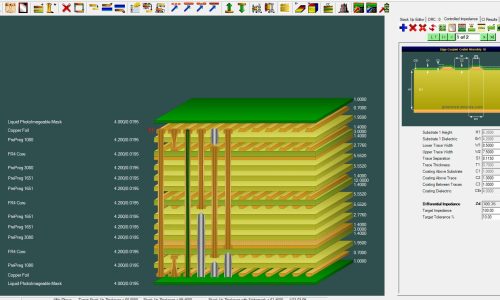

Benefits of using HDI

- Lower costs

- Reduces diapers, up to 33% fewer diapers

- Reduces size, at least 40% smaller

- Performance improvement

- PCB miniaturization: thinner, lighter and smaller

- Increased wiring density, via-in-pads allow tighter part spacing

- Removal of decoupling capacitors

- Closer ground planes

Benefits of using HDI

- Access to advanced packages

- Ease of use of FPGAs

- No dogbone / via are needed only on the outer layers

- Fewer layers required to carry large FPGAs

- Improved reliability

- Microvias has been tested as the most reliable for organic substrates

- Improved thermal efficiency

- HDI uses thin dielectrics, high temperature sdielectrics and copper filled vias

Would you like a quote?

PCB technology, our passion at your service

We are one of the leading manufacturers of PCBs and HDI printed circuits dedicated to time and technology in France and Europe.

Continue to push the boundaries with a focus on quality and innovation.

Our capacity covers a wide range of technologies and market sectors.

We have over 20 years of R&D experience to develop new technologies and products.